A solid, printable electrolyte enables lithium-ion batteries to take many shapes

Engineers dreaming up new pacemakers, watches, or whatever wearable gadgets come after Google Glass have to tailor their designs around existing battery shapes—typically cylinders, pouches, or rectangles. But a team of researchers hopes their fully printable, flexible lithium-ion batteries will one day free designers from these constraints (Nano Lett. 2015, DOI: 10.1021/acs.nanolett.5b01394).

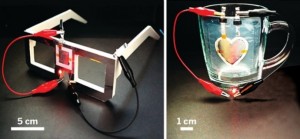

Thin, flexible lithium-ion batteries printed onto the bridge of a pair of paper glasses (left) and the curved surface of a glass mug (right) can power small light-emitting diodes.

Battery shapes are now limited because of the need to contain liquid electrolytes, which carry ions and charges between the two electrodes when the battery is being used or recharged. Solid-state batteries that use solid electrolytes could be printed to fit a particular device shape and would give designers more room to play. So far, though, there aren’t any solid-state lithium-ion batteries on the market, says Corie Cobb of PARC, a research company owned by Xerox, in Palo Alto, Calif., who is not involved in the new work. Lithium-ion is currently the best rechargeable battery chemistry—it lasts a long time, has a high energy density, and delivers that energy in powerful bursts.

Sang-Young Lee of Ulsan National Institute of Science & Technology, in South Korea, and his group have now shown they can print working batteries on a variety of surfaces and in different shapes. Two years ago, Lee’s team designed a printable, solid-state electrolyte for lithium-ion batteries (Adv. Mater. 2013, DOI: 10.1002/adma.201204182). This material has a unique combination of properties: It’s sufficiently conductive, has the right viscosity for printing, and maintains its function even when the battery is repeatedly flexed or fixed onto a curved or bent surface. The electrolyte Lee designed is a composite made of alumina nanoparticles and lithium combined with polymer that can be cured by ultraviolet light. “Before printing, the material has the viscosity of ketchup,” Lee says.

To print working batteries, Lee’s group first creates printable inks by mixing previously developed battery-electrode material blends into the UV-curable polymer. They press ink for the anode through a stencil with a squeegee, cure it with UV light, then do the same with the electrolyte on top of the anode. They follow that with the cathode ink to create the full battery cell. Using this technique, the researchers printed a battery on the bridge of a pair of paper glasses and also put a heart-shaped battery on the curved surface of a glass mug. Lee says this stencil printing can be done on a massive scale.

Cobb says solid electrolytes tend to have limitations—they’re not as conductive as liquid ones. She’d like to see more data on the performance and energy storage of these batteries but says they do demonstrate the potential to make a greater variety of designs and shapes that aren’t possible today.

These printed batteries can power small light-emitting diodes but need a lot of improvements, Lee acknowledges: They can only keep going a short time before they must be recharged. The researchers are now printing batteries with better lithium-ion materials. “Changing the shape and design of batteries is a new playground for battery researchers,” Lee says.

- Chemical & Engineering News

ISSN 0009-2347

Copyright © 2015 American Chemical Society